Some Known Questions About Dust Extractor Vs Shop Vac.

Table of ContentsAll about Dust Extractor Vs Shop VacHow Dust Extractor Vs Shop Vac can Save You Time, Stress, and Money.The Best Strategy To Use For Dust Extractor Vs Shop VacThe Greatest Guide To Dust Extractor Vs Shop VacThe Definitive Guide for Dust Extractor Vs Shop Vac

Prior to the growth of dust collection systems, dirt explosions, especially in woodworking shops, were really common. The trouble was so common that several stores had a wall available to the outside. Similar to fire avoidance, dirt collection systems keep air moving and distributing to avoid the opportunity of dust gathering adequately to generate an explosion bubble.

Dirt collection systems may get perplexed with air conditioning, they have much much more advantages. Smell reduction is not usual in all dirt collection systems.

Dust Extractor Vs Shop Vac Can Be Fun For Anyone

Offense of these standards can result in a company being closed, that makes it important to install an appropriate dirt collection system. Something that is seldom considered in an industrial atmosphere is the tidiness and top quality of the flooring. One of the advantages of a dirt collection system is the removal of the need to frequently cleanse the floor.

Compliance with federal government laws is the most crucial of all the inspiring elements for mounting a dirt collection system. A dirt collection system is necessary for any type of industry that creates gasses, dust, overspray, or various other kinds of particle matter.

Some Of Dust Extractor Vs Shop Vac

Most of the procedures that use dirt collection systems are generally worried about safety and security because numerous procedures involve making use of gasses. Plasma cutters generate fine smoke as well as fumes, which require to be removed to secure the driver. Dust collection systems for plasma cutters utilize particularly designed downdraft tables to attract the fumes far from the work area as well as employees.

Various types of dirt collection systems are used to capture as well as accumulate the hazardous matter generated by welding. Because welding fumes as well as dirt can be eruptive, the product generated must be examined for its fire and explosive features based on the standards of OSHA and the National Fire Protection Association's, Association (NFPA).

The volatility of the dirt from seed as well as grain procedures is so high that OSHA has a set of standards especially created for these visit this website operations. Dust from seed and grain operations varies according to the kinds of materials being moved. It can be rough, sticky, or exceptionally great. This is better made complex by the wide variety of equipment used in review seed and grain operations, that include conveyors, lifts, containers, numerous kinds of vents, silos, and also mixers.

An Unbiased View of Dust Extractor Vs Shop Vac

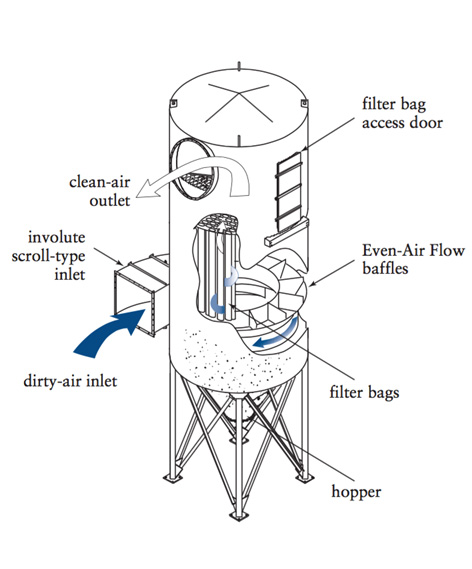

Baghouse enthusiasts are utilized for their high efficiency of 99% and also integrity. The first issue for air quality in the office began with woodworking since it produces large quantities of sawdust and fumes. As manufacturers have explored the various woodworking procedures, they have located that a large variety of particulate matter is produced.

Lumber mills and also sawmills need various dust collection systems than timber pellet manufacturers. Each kind of operation calls for a different kind of collection system. No matter the kind of woodworking operation, timber dirt has been found to be the major root cause of dust mishaps. The threats of dirt from woodworking operations are extremely ignored.

Both kinds of dirt collection systems for woodworking operations are cartridge and baghouse, with baghouse being the most reliable. Despite the kind of system selected, it has actually to be designed as well as engineered to specifically fit the operation as well as manufacturing procedure of the consumer. The main problem for dirt collection systems in the food processing sector is transportation, storage space, as well as mixing, which are the locations that build up one of the most dirt.

Dust Extractor Vs Shop Vac - The Facts

Food processing includes conveyors, packing equipment, mixers, shelling machines, and focused storage space locations. Filtering systems can be linked to all equipment and areas. The unique demands of food handling need stainless steel because it is approved for procedures included in food production. Both firms that control air top quality for mining procedures are the Epa (EPA) and the Mine Safety And Security and also Health And Wellness Administration (MSHA), a Go Here branch of the Division of Labor.

Dust control systems for mining procedures should endure hefty use yet be flexible adequate to adjust to a wide array of conditions. The nature of mining dust calls for really strong and trusted tools because mining dirt can be harsh and rough along with incredibly fine. The different types of mining establish the kind of dust collection system (dust extractor vs shop vac).

No matter the procedure, mining dirt control systems are made to subdue explosions, isolate fumes, as well as control smells from gasses. The usual kinds of dust collection systems for mines are baghouse as well as cartridge. Fiberglass dust is a significant health danger that can trigger eye, skin, and also lung irritation. The dimension of the dust fragments differs relying on the kind of operation, with specific materials having the possible to ignite.